Amyloflex 5050 granule

Product Features

Amyloflex 5050 containing about 50% tapioca starch is a certified compostable granule product in compliance with European EN13432 standards. It is made by compounding with an equivalent amount of poly(butyleneadipate-co-terephthalate)(PBAT) applicable for thermal extrusion processes making film products. Amyloflex 5050 exhibits the following advantages for users.

1. No switch cost: Amyloflex 5050 can be easily processed on the regular film-blowing or casting machinery without change.

2. No additive is required for anti-blocking or lubricating purpose.

3. Excellent resilience to recycling process.

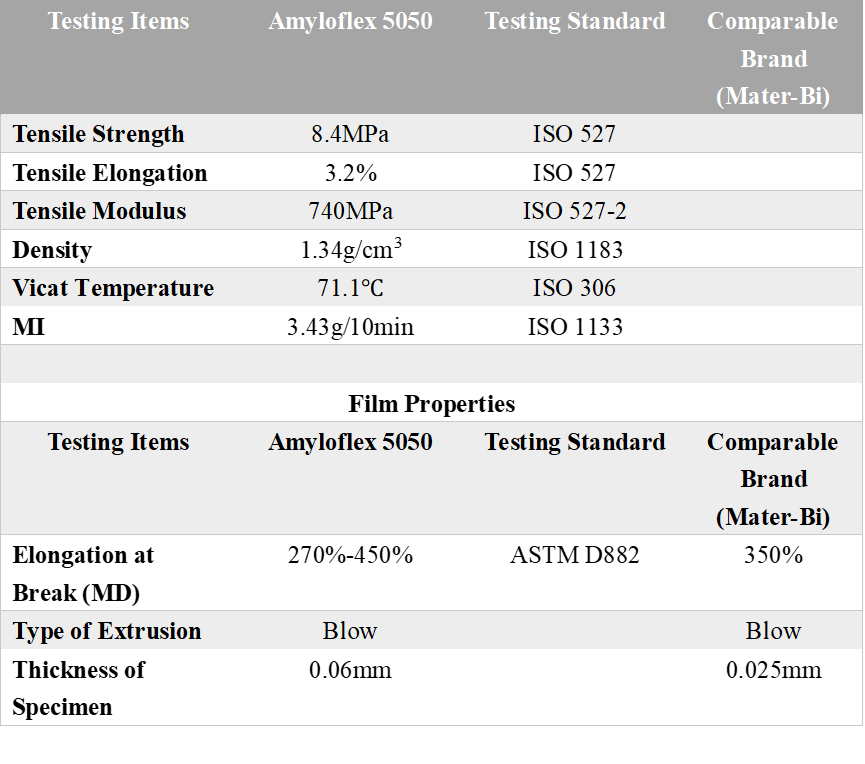

Product Specifications

Applicable Extrusion Processes

Prior to processing, the Amyloflex 5050 granules are recommended to be dried at 80℃ for 4 hours.

Film blowing:Amyloflex series can be used to make film products by use of standard film blowing machinery. The recommended thermal extrusion temperature profile is 140℃-170℃ along with the die temperature at 130℃ -140℃. It could need to be slightly adjusted for optimal parameters due to the machinery variation.

Film casting: Amyloflex 5050 granules are also applicable for standard casting equipment. The extrusion profile is similar to the film blowing process and 170℃ is recommended for T die in the beginning. The optimal parameters need to be adjusted in practice.

Tests and Certification

Subject to the European standard EN13432, the Amyloflex 5050 granular product is certified by DIN CERTCO as a compostable material (registration numbers 7W0339 and 9K0059).

Download